D&RGW #464

Ridgway Yard - Version 6

December 23, 2023

Well, here we go again... Starting with the earlier version of the Ridgway track plan, I started the process of transferring the plan to the bench work. I started with engine facility. It only required a few minor revisions. I substituted a 65' turntable for the 55' prototype in order to turn K-27's in lieu of using the wye at Placerville. More on the Placerville wye below.

When it came to the yard itself, there were a number of problems. First, the Ridgway siding/arrival departure track turned out to be about 4 or 5 car lengths too short. Since I couldn't extend the siding towards the engine facility, I extended it south towards Old Placerville. In addition, I decided to substitute three stub end yard tracks for the three double ended ones in the original plan for additional capacity. The stock pens were also moved to the opposite (correct) side of the yard.

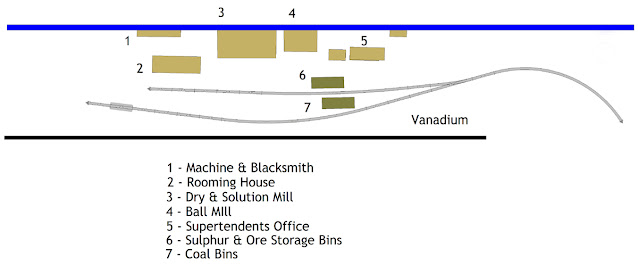

Here is the current state of the Ridgway yard.

Old Placerville

The changes to the Ridgway yard also impacted the space available for Old Placerville. As a result, I decided to eliminate the Placerville wye and use a 65' turntable at Ridgway to turn locomotives. The change also made room for one or more Montrose staging tracks oriented in the proper direction.

I built the stock pens using parts from two Banta Modelworks kits. The fuel oil distributor is another group of structures off Bruce Hanley's layout.

Here is the overall plan for Ridgway and Old Placerville.

The Gandy Dancers arrive in Old Placerville

Dec;ember 29, 2023

I finally got my hands on about 40' of good used Code 70 flex track off ebay. The track, along with some turnouts built over the Christmas holiday allowed for additional track work. Here is #463 working the old Placerville spur. I like to run a train over and trouble shoot each section of new track. Turns out the cylinders of 463 only clear the stock yard ramps by a about 1/16".

The Gandy Dancers arrive in Ridgway

Dec;ember 31, 2023

After 5 months of construction, the first train arrives in Ridgway. I don't have enough flex track to finish off all the yard tracks but I should be able to reach the turntable and install a couple of storage tracks near the engine facility. I am also waiting for some QuickSticks laser cut turnout ties from Fast Tracks.

December 31, `2023

I had just enough track to reach the turntable and install the three storage tracks behind the lead. Here the #463 finally gets to take a spin on the Ridgeway Turntable. I used a 9 volt battery to test out the turntable; eventually the job will be done by a decoder.